How To Build A Glass Vivarium :

A vivarium bought in a pet-shop is quite expensive, and if one would like a custom build vivarium that fits certain proportions, it is even more expensive.

It is fairly easy, although time consuming, to make a vivarium, so why don't you ?

The vivarium in this instruction is cubic and measures roughly 34x34x34 cm. The hardest part of the job is to cut the glass. One could "cheat" and buy the glass pre-cut from a glazier. This will off course make the vivarium more expensive, but it is still worth the trouble.

What you need to complete the cubic vivarium are the following:

3 pieces of glass 34x34x0,3 cm (sides and floor)

1 piece of glass 34x30x0,3 cm (top)

1 piece of glass 34x33x0,3 cm (back)

1 piece of glass 33x10x0,3 cm (front)

2 pieces of glass 22x18x0,3 cm (sliding doors)

1 piece of perforated aluminum plate 1x33 cm

1 piece of perforated aluminum plate 4x34 cm

Glass-silicone

1 set of sliding door lists 33 cm long and suitable for 3 mm glass

Roughly 4,5 meters of aluminum or plastic angle list (I have used black plastic 15x15 mm)

Acetone

Tooth-picks/matches

Adhesive tape

Tools:

Glass cutter

Mitre box and fine toothed saw

"Silicon-gun"

Folding-rule

Garden shears (the easier way to cut the sliding door lists)

The Working Procedure :

1. The first thing to do is to de-grease all the edges of the glass pieces. Use the acetone for this. Make sure to do it in a well ventilated area as acetone emits harmful vapours. When you have de-greased the edges, try not to touch them with you bare hands any more.

2. The next thing to do is to fix matches/tooth-picks to the glass with the adhesive tape. This is done to make some space between the glass pieces to fill with silicone.

3. Attach the 2 sides, the front and the back of the vivarium to each other, using adhesive tape, and place them on top of the floor piece. Do not put the top of the vivarium in place yet !

5. Remove the toothpicks/matches and fill the remaining gaps with silicone. When this is done, glue the top-piece in place using silicone.

4. Make sure the sides, back and front are placed correctly on the floor piece and fill the space between the glass with silicone. Leave some silicone-free areas around the toothpicks/matches. I find it more easy to do the silicone-filling from inside of the vivarium. Leave to harden over night.

6. Glue the perforated aluminum strip in place on top of the vivarium.

7. Glue the perforated aluminum strip in place at the front of the vivarium. Leave to dry over night.

8. Mount the sliding door lists using silicone. Make sure they are parallel.

9. Mount the angle lists using silicone

10. Fit the sliding doors in the sliding door lists.

11. The vivarium is done !

Please Note : It is important always to work in a well ventilated area when using acetone and silicone. Watch out for sharp edges on the glass pieces. Do not use the vivarium the first 4 days after completion, as the silicone might still emit vapours.

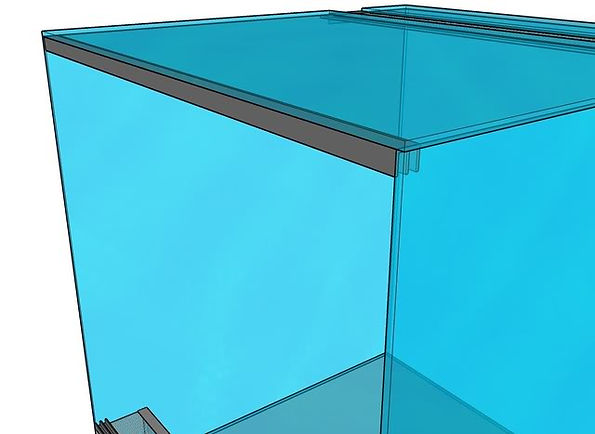

DIY Glass Open Front Vivarium:

courtesy to : www.reptileforums.co.uk

Introduction to Building Your Own Vivarium

If you want to try, building an open front vivarium from scratch, you will find this a challenge and satisfying as well. I have attempted to try and document this process as accurately as possible, from tips, materials list, pre-assembly instructions, and complete step-by-step directions on how to construct an open front vivarium from 4 mm glass.

Tips on Working with Glass

***8226; Plan ahead: Prepare good schematic drawings, before cutting the glass. >> See Cut Size Calculator

***8226; Insure a correct fit by using accurate measurements.

***8226; I construct my vivariums with the two side pieces of glass and the back piece to fit on the outside of the base and the front door strut set on top of the bottom base sheet of glass. >> See Panel Placements Diagram

***8226; Have a professional glazier cut and prepare your glass if you do not feel comfortable with cutting glass.

***8226; Lightly rubbing down all the edges on the newly cut glass, with the emery cloth helps prevent small chips and you cutting yourself.)

***8226; If at any time during construction you have trouble with the tape not sticking to the glass, just clean the area with some acetone on a paper towel and try again

***8226; Use a glass pencil or a Marker pen to note the orientation on each piece of glass.

***8226; Drill any holes for drainage and misting systems before assembly

Materials List

The glass components consist of 1 bottom, 1 back, and 2 sides, 2 top pieces of glass, 1 door strut, 1 retaining lip and 2 doors. (Optional ***8211; 1 False Base)

You will also need the following items to construct your vivarium.

***8226; Sturdy, flat and non-abrasive surface to work on

***8226; Single edged razor blades

***8226; Acetone or methylated spirits

***8226; A non-toxic 100% silicone sealant (Aquarium Grade)

***8226; A roll of paper towels.

***8226; A Glass pencil or marker pen.

***8226; A roll of duct tape or a good quality masking tape

***8226; Emery cloth or silicone carbide sandpaper.

***8226; ***8220;E***8221; profiled plastic (4mm) strips (Door Channels)

***8226; ***8220;L***8221; profiled plastic angle strips

***8226; Fine Stainless Steel Mesh

***8226; Small block of natural bees wax

***8226; Good pair of kitchen scissors

***8226; Thin latex or similar gloves

***8226; Small Right-Angle or Engineers square

***8226; 1x Large wooden Block or cloth covered Brick

***8226; Small amount of dishwashing soap and water

***8226; Small Polystyrene blocks (for optional False Base)

Pre-Assembly Preparations

***8226; The door strut has an arch cut out of it, you can cut this free-hand or use a template, otherwise have this piece of glass cut by your local glazier.

***8226; Once the pieces of glass are cut, using the emery cloth or silicone carbide sandpaper, buff all the raw edges of the glass just enough to take off the sharpness.

***8226; Clean all the glass pieces joint areas and edges (any area where silicone will be applied) with acetone or methylated spirits.

***8226; Cut strips of tape, at least 16 ***8211; 18 pieces, about 120mm long. Stick these to a clean surface, which the tape won't stick too much to, with at least half of the tape hanging freely. If you require more tape, cut these before installing another piece.

BEFORE you start to assemble your vivarium, it is important to know in what sequence the glass sheet are assembled.

The sequence is as follows:

1. Base

2. Back

3. Left Side

4. Inside Retaining Lip

5. Door Strut

6. False Base (Optional)

7. Right Side

8. Top ***8220;Back***8221;

9. Top ***8220;Front***8221;

10. Stainless Steel Mesh

11. Plastic Angle

12. Top Vent retainer strips

13. Door Channels

14. Doors

If you are going to install the optional false bottom, you can cut an arch (See Door Strut) in the bottom of the back piece, to allow access under the false base.

As each piece of glass is installed, you will need to apply a thin and adequate line of silicone to each inside edges of sheets that are being joined.

DO NOT wipe off any excess silicone that might squeeze to the outside edges of the glass. This can be cleaned up or trimmed later on, once the silicone has fully cured.

Step-by-Step Assembly Instructions

Prepare for assembly, by arranging your glass pieces in the order that you will need them and all other tools and materials within easy and comfortable reach. Make sure you know what the orientation of each piece is (use a marker to write on each piece) N.B. Keep all writing and marking at least 25mm from edges to be siliconed.

Example:

Ensure that your work surface is flat, sturdy, non-abrasive and that you have sufficient room, so that you can easily reach everywhere on the vivarium, once you start working.

1. BASE :

***8226; Use a marker pen to draw a parallel line, 45mm from the front edge of the base.

***8226; Then turn the base piece over, so that this line is now on the underside.

***8226; Stick X6 pieces of tape on the underside of the base, with ½ of the tape still showing. (x2 pieces on the back edge and x2 pieces on each side edge), the sticky side should now be facing up.

2. BACK

***8226; Have the block of wood or cloth covered brick ready to support the back piece of glass.

***8226; Apply a thin but sufficient bead of silicon along the bottom inside edge of the back piece.

***8226; Carefully align the back piece to the outside back edge of the base.

***8226; Press the back with a light, but firm pressure to bed it into the silicon.

***8226; Use the Block or brick to support the back in the upright position.

***8226; Use the Right angle or Square to check that the two pieces of glass are at right angles to each other.

***8226; Fold the x2 pieces of tape upwards and stick them to the back; this will assist in keeping everything in the correct place.

Tip: This step is much easier to do with an assistant to hold the front glass pane upright and in place while you complete installation of the first side piece in the next step.

3. SIDE (Left-Hand)

***8226; Apply a thin but sufficient bead of silicon along the bottom and back inside edges of the side piece.

***8226; Carefully align the side piece to the outside side edges of the base and back.

***8226; Press the side piece with a light, but firm pressure to bed it into the silicon.

***8226; Fold the x2 pieces of tape upwards and stick them to the side; this will assist in keeping everything in the correct place.

***8226; Use x2 pieces of tape and stick them across the back and side joint, this will assist in keeping everything in the correct place and in the upright position.

4. INSIDE RETAINING LIP

***8226; Apply a thin but sufficient bead of silicon along the bottom and left hand edges of the retaining lip piece.

***8226; Carefully align the retaining piece to the line drawn on the underside of the base.

***8226; The retaining piece should be placed just behind the line and against the left side piece.

***8226; Press the piece with a light, but firm pressure to bed it into the silicon.

***8226; Use the Right-angle or Square to check that the retraining piece is at right angles to the base.

5. DOOR STRUT

***8226; Apply a thin but sufficient bead of silicon along the bottom and left hand edges of the door strut.

**8226; Carefully align the door strut to the top front edge of the base.

***8226; The door strut should be placed on the base front edge and against the left side piece inside front edge.

***8226; Press the piece with a light, but firm pressure to bed it into the silicon.

6. SIDE (Right-Hand)

***8226; Apply a thin but sufficient bead of silicon along the side edges of the Door Strut and the retaining lip pieces.

***8226; Apply a thin but sufficient bead of silicon along the bottom and back inside edges of the side piece.

***8226; Carefully align the side piece to the outside side edges of the base and back.

***8226; Press the side piece with a light, but firm pressure to bed it into the silicon.

***8226; Fold the x2 pieces of tape upwards and stick them to the side; this will assist in keeping everything in the correct place.

***8226; Use x2 pieces of tape and stick them across the back and side joint, this will assist in keeping everything in the correct place and in the upright position.

7. With most of the pieces in place and the vivarium constructed, run an adequate solid line of silicone into the joint areas on the inside, then run your finger over the silicone from one end to the other of each seam, preferably in one continuous motion, to smooth the silicone down and force it into the joint areas.

Tip: Dip your finger into a little water and dishwashing soap, before smoothing down the joints. (10 drops of soap in a glass of water)

8. TOP “BACK”

• Apply a thin but sufficient bead of silicon along the back and side bottom edges of the top-back piece.

• Carefully align the top-back piece to the top edges of the base and sides.

• Press the top-back piece with a light, but firm pressure to bed it into the silicon.

• Use x2 pieces of tape and stick them across the back and top joint, this will assist in keeping everything in the correct place.

• Use x2 pieces of tape and stick them across the side and top joints, this will assist in keeping everything in the correct place.

9. TOP “FRONT”

• Apply a thin but sufficient bead of silicon along the side bottom edges of the top-front piece.

• Carefully align the top-front piece to the top edges of the sides.

• Press the top-front piece with a light, but firm pressure to bed it into the silicon.

• Use x2 pieces of tape on each side and stick them across the side and top joints; this will assist in keeping everything in the correct place.

10. With last two pieces in place, run an adequate solid line of silicone into these last few joint on the inside and then run your finger over the silicone from one end to the other of each seam, preferably in one continuous motion, to smooth the silicone down and force it into the joint areas.

Tip: Dip your finger into a little water and dishwashing soap, before smoothing down the joints. (10 drops of soap in a glass of water)

11. Allow the silicone to cure for 24 hours.

12. BOTTOM VENT

• Measure the distance on the inside of the left and right sides above the door strut.

• Repeat this for the above the retaining lip.

Now cut two sections of the “L” shaped profile to fit each of section.

Measure the distance from the front of the door strut to the back of the retaining lip, on the left-hand side.

• Repeat this for the right-hand side.

These measurements are used to determine final size of the Stainless Steel mesh for the vent to the correct size.

• Use masking tape to cover both sides of the stainless steel mesh (stick this wider than your measurements)

• Use a marker pen to draw out your measurements on the tape.

• Cut along these lines.

Tip: By using the masking tape, it makes it easier to draw lines in the mesh. The masking tape also reduces stray stainless steel wire splinters flying about or puncturing your hands. The finished cut is a lot neater as well.

Check that the newly cut mesh fits over the retaining lip and door strut.

• Make any adjustments if required.

• Apply a thin but sufficient bead of silicon along the top edges of both the retaining lip and the door strut.

• Place the stainless steel mesh back into its correct position.

• The “L” profile sections are now placed over the edges

• Press the “L” profile sections with a light, but firm pressure to bed them and the stainless steel mesh into the silicon.

Use x6 pieces of tape and stick them across the top and down the sides of the strut and lip, this will assist in keeping everything in the correct place.

13. TOP VENT (PART 1)

• Measure the width of the top gap on the inside of the left and right sides.

• Measure the length of the top gap on the outside of the left and right sides.

These measurements are used to determine the final size of the Stainless Steel mesh for the vent.

• The total width of the mesh for the top vent should be the width of the gap, plus 20mm.

• This will give an additional 10mm flange on each long edge, secure the mesh to the top of the viv.

• The total length of the mesh is equal to the total outside width of the viv.

• The four corners are cut to allow proper placement.

• These notches are 10mm x the width of the glass used for the sides.

Tip: By using the masking tape, it makes it easier to draw lines in the mesh. The masking tape also reduces stray stainless steel wire splinters flying about or puncturing your hands. The finished cut is a lot neater as well.

1. Use masking tape to cover both sides of the stainless steel mesh (stick this wider than your measurements)

2. Use a marker pen to draw out your measurements on the tape.

3. Cut along these lines.

4. Use masking tape to cover both sides of the stainless steel mesh (stick this wider than your measurements)

• Now cut two sections of the “L” shaped profile to fit each of section.

• Check that the newly cut mesh fits over the retaining lip and door strut.

• The small tabs on the ends of the mesh sit on top of the sides and the 10mm flanges, fit under the top pieces of the viv.

• Make any adjustments if required.

• Apply a thin but sufficient bead of silicon along the top edges of both the retaining lip and the door strut.

• Place the stainless steel mesh back into its correct position.

• The “L” profile sections are now placed over the edges

• Press the “L” profile sections with a light, but firm pressure to bed them and the stainless steel mesh into the silicon.

• Use a pieces of tape and stick them across the underside of the mesh and top peices of glass, this will prevent the mesh from sagging while the silicon is curing on the edge strips.

14. Allow the silicone to cure for 24 hours.

15. HALFWAY

• Remove all the tape.

• All that is left to do is the 2nd part of the top vent and the installation of the sliding doors.

16. TOP VENT (PART 2)

• Carefully turn the viv upside down.

• Measure the width of the top of the viv, inside the sides.

• Cut x2 strips of 2mm glass, 15mm wide.

• The length should be just short of the top inside measurement.

• Apply a bead of silicon along the centre of each strip.

• Place the two strips (silicon side down) over the edges of the stainless steel mesh.

• Align the edges of the strips with the edges of the top vent of the viv.

• Press the two strips with a light, but firm pressure to bed them and the stainless steel mesh into the silicon

• Place a block or Cloth covered brick over the strips to weight them down.

17. Allow the silicone to cure for 4 hours.

These strips seal and protect the edges of the stainless steel mesh on the top mesh

18. DOORS (Tracks)

This stage requires two different types of “E” profile.

1. Bottom Profile (Shallow).

2. Top Profile (Deep), this is about twice as deep as the bottom profile.

The profile you use should match the thickness of glass, that you are going to use for the doors.

• Measure and cut a length of top (deeper) profile to fit under the top inside of the front of the viv.

Check that the newly cut top profile fits in the top front of the viv, with abot a 1mm play on eack side.

• Make any adjustments if required.

• Apply a bead of silicon along the centre of the top profile.

• Carefully align the top track profile to the bottom front edge of the top and sides.

• Check that the newly cut bottom profile fits, with about a 1mm play on each side.

• Make any adjustments if required.

• Apply a bead of silicon along the centre of the front “L” profile above the door strut.

• Press the profile with a light, but firm pressure to bed it into the silicon.

20. BOTTOM TRACK

• Measure and cut a length of bottom (shallower) profile to fit on-top “L” profile of the door strut, in the front of the viv.

• Carefully align the bottom track profile to the front edge of the sides.

• Press the profile with a light, but firm pressure to bed it into the silicon.

21. Allow the silicone to cure for 4 -6 hours before trying to fit the doors.

22. DOORS

To work out the dimensions of the sliding doors, the following measurement are required to be taklen.

1. The internal width of the viv at the front.

2. The height between the top and bottom tracks.

3. The depth of the top track.

• Calculating the width if the two sliding doors:

1. Divide the internal width by 2.

2. Add 5mm to the above result.

3. The final result is the width measurement for each of the two sliding doors

The 5mm added to each door, result in the overlap, when the doors are placed in the tracks.

• Calculating the height if the two sliding doors:

1. Add the depth of the top track and the height between the top and bottom tracks.

2. Subtract 2mm to the above result.

3. The final result is the height measurement for each of the two sliding doors

The 2mm deduction allows just enough clearance when lifting the doors in and out of the tracks.

23. FITTING THE DOORS

• Before fitting the doors, make sure that all the edges have been rubbed down properly.

• Pay a little more attention to the corners of each door, ensure that they are rounded off and smooth.

• Take a small block of pure bees wax and lightly rub it along the top and bottom edges of each door.

• Check that there are no obstructions in the tracks.

The doors are fitted in a sequence; this sequence is used in reverse when you want to remove the doors.

A. Hold the First door by the sides.

B. Insert the top edges into the top track channel furthest from the front.

C. Lightly push the door all the way, up into the track.

D. Gently swing the bottom of the door over bottom track.

E. The door should just clear the bottom track.

F. Position the door over the furthest channel in the bottom track.

G. Carefully lower the door in the channel.

H. The door should now sit in the both the top and bottom track and slide side to side.

Repeat the above steps to insert the other door into the channel closest to the front.

To remove the doors, this process is followed in reverse.

24. At this stage you have a complete working viv.

25. But there are a few additions that can be made to improve the ways that the doors seal.

26. DOOR SIDE CHANNELS

27. DOOR OVERLAP GASKET

Select from more than 15 DIY projects..